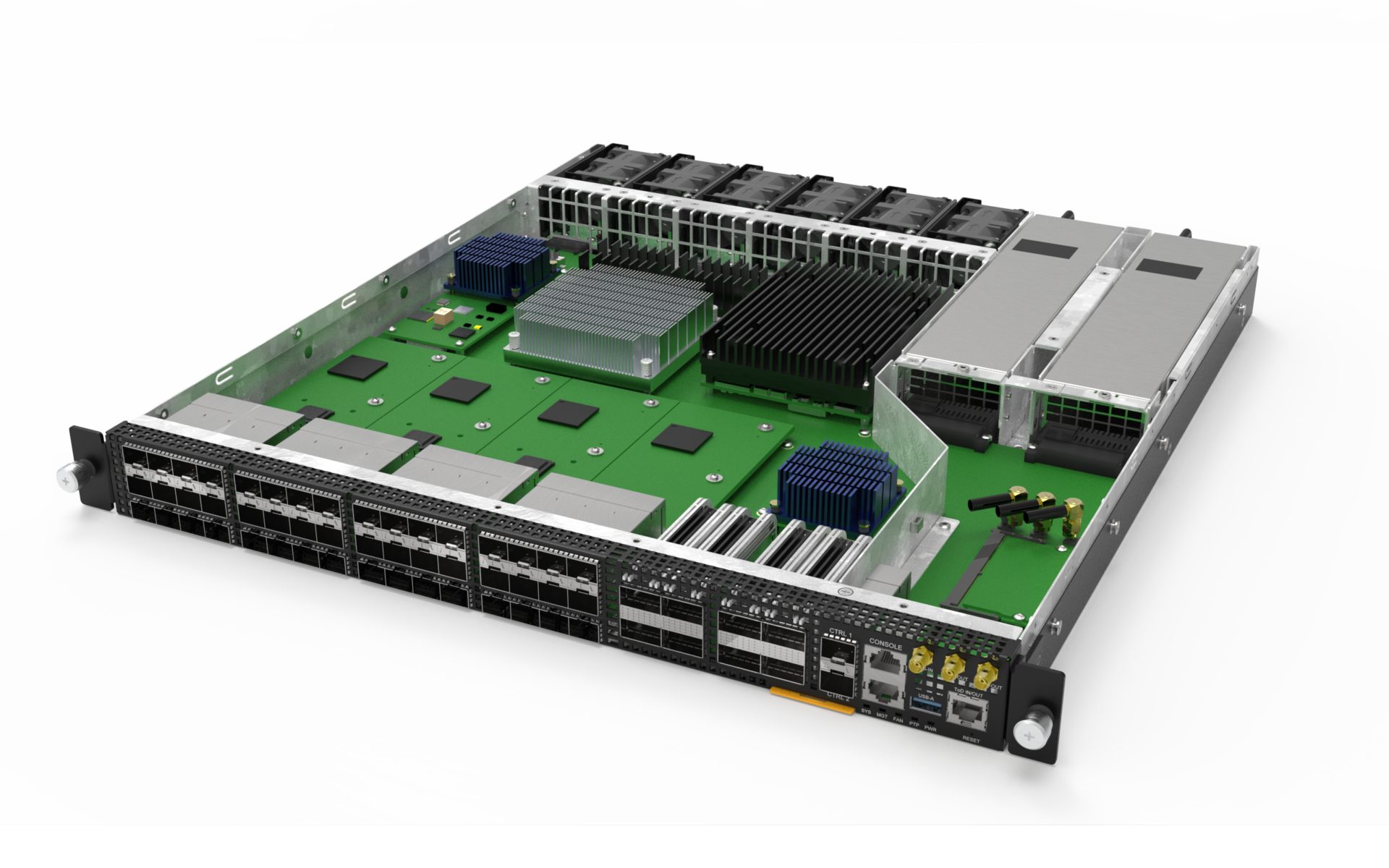

Mechanical Packaging

Mechanical Packaging is much more than a Metal Box

A common component of a product or module design is to provide the mechanical design. In fact, in optimized high performance and high speed system designs, it can be mandatory for the mechanical housing to be considered in lock step as a part of the overall system design.

There are many factors that drive such requirements:

- Precise mechanical dimensions and appearance to match existing products or modules in the same product series.

- Leverage the metal housing as integral heat conductive surface in contact with the electronics for sake of conductive, radiant and convention cooling.

- Consideration of overall chassis airflow and direction, ensuring that circuit boards, mounted components and RF shielding do not create airflow ‘dead spots’, while ensuring holes in modules are sufficient in size and line up with overall system cooling design.

- Sufficient mechanical strength and ruggedness, especially important where requirement of intended location indicate possible direct impact, vibrations and shock.

- Environmental factors such as operating temperature range, moisture, and humidity.

- Complex mechanical designs that include modules that slide in and are removable that mate with connectors including hot-swappable modules that provide redundancy and serviceability.

- Electromagnetic emissions and susceptibility, where mechanical housing acts as a Faraday cage and other shielding.

- Mechanical housing acts as an efficient method to achieve ‘low noise’ through common grounding and decoupling.

Products, modules, and circuit board designs created by APS Networks and its design partners are used in applications from office environments to datacenters.