Mechanical Packaging

Mechanical Packaging is much more than a Metal Box

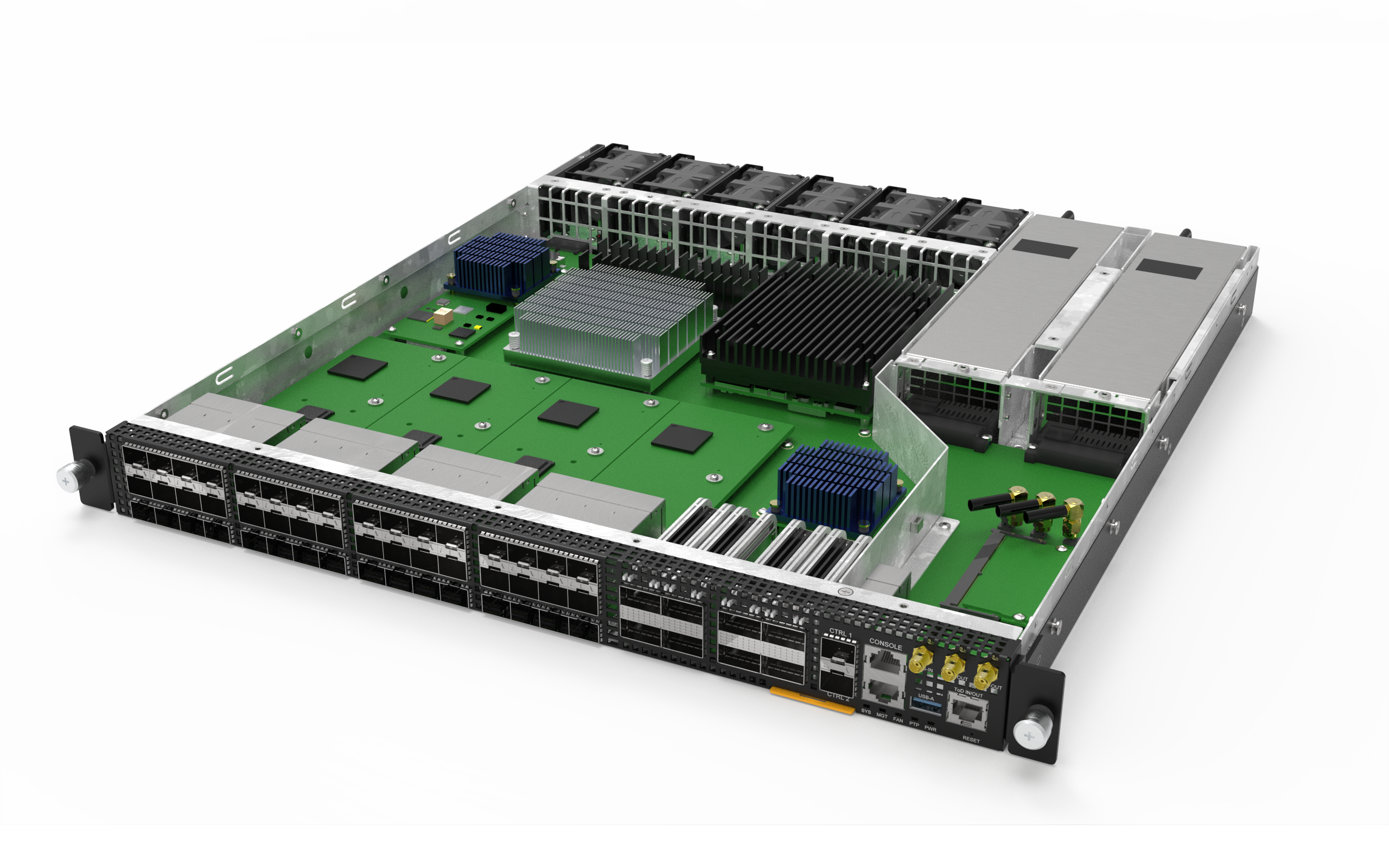

A common component of switch development is to provide the mechanical design.

In fact, in optimized high-performance and high-speed system designs, it can be mandatory for mechanical housing to be considered in lockstep as a part of the overall system design.

Right from the start, in the mechanical engineering phase of the development, all (physical) requirements are determined and documented.

There are many factors that drive such requirements:

- Matching the exact mechanical dimensions of the new product to the units in the same product line

- Chassis airflow and direction

- Ruggedness and mechanical strength

- Environmental factors: operating temperature, moisture, humidity

- Need for Hot-Swappable modules

- Electromagnetic emissions

- .... and many more!

Based on these requirements, our team of mechanical engineers starts to work on the actual physical design of the circuit board in conjunction with the primary placement layout. Once the detailed board layout has been completed by our hardware team, the mechanical engineers continue with the integration of the mechanical components of the system.

Mechanical Engineering & Factory Introduction

Because of the nature of the work, our mechanical engineers have a close working relationship with our Factory Introduction team. Both are focused on the manufacturability of the end product in the factory.

The interworking of both teams reinforces optimization. Both teams look at the labor intensity considered, the different types of components applied in the design, and the sheer number of components used.

That is why Mechanical Engineering is one of the most important subdivisions of engineering and why it plays such an important role in our Switch Development.

The APS Networks Advanced Programmable Switches are used in applications from Network Security, Media & Broadband and anything in between.

Download our Mechanical Packaging Design Brief and find your switch application.